Your choice of plated through-holes or filled vias

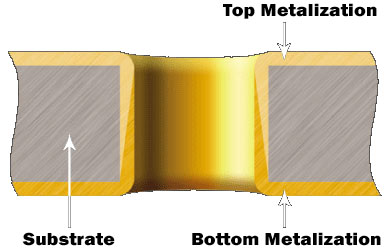

Plated Through Holes and Slots provide reliable electrical paths to the ground plane or back side pattern.

These connections provide a convenient, compact means of obtaining ground connections

without needing to use ribbon bonds or conductive epoxy. Most of the time the metalization is fully sputtered in order to provide optimal adhesion and reliability but the metalization can also be electroplated, depending on the designated metalization scheme.

Plated Through Holes

The Plated Through Holes and Slots are laser machined into the substrates and then specially cleaned in order to remove any laser slag. There are a few design concerns with Plated Through Holes and Slots, namely, maintaining a proper aspect ratio (ratio of the hole diameter to the substrate thickness) so the hole barrels fully metalize and maintaining large enough capture pads (annular ring or border).

Edge wrap around techniques, including patterned edge wraps, can connect isolated front-to-back conductors.

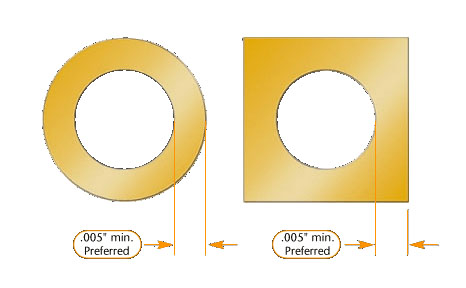

Capture pad details.

Design Guidelines

UltraSource offers three types of solid filled via circuits. They are available on alumina (Al2O3), aluminum nitride (AlN) and beryllium oxide (BeO) substrates and are post polished to provide a high quality, planar surface.

- Solid gold (Au) filled vias

- Solid copper (Cu) filled vias

| Substrate Thickness | Allowable Hole Diameter Ranges |

|---|---|

| .005″ | .003 – .005″ |

| .010″ | .006 – .010″ |

| .015″ | .008 – .015″ |

| .020″ | .010 – .018″ |

| .025″ | .012 – .020″ |

Plated through-hole sizes