QUALITY MANAGEMENT

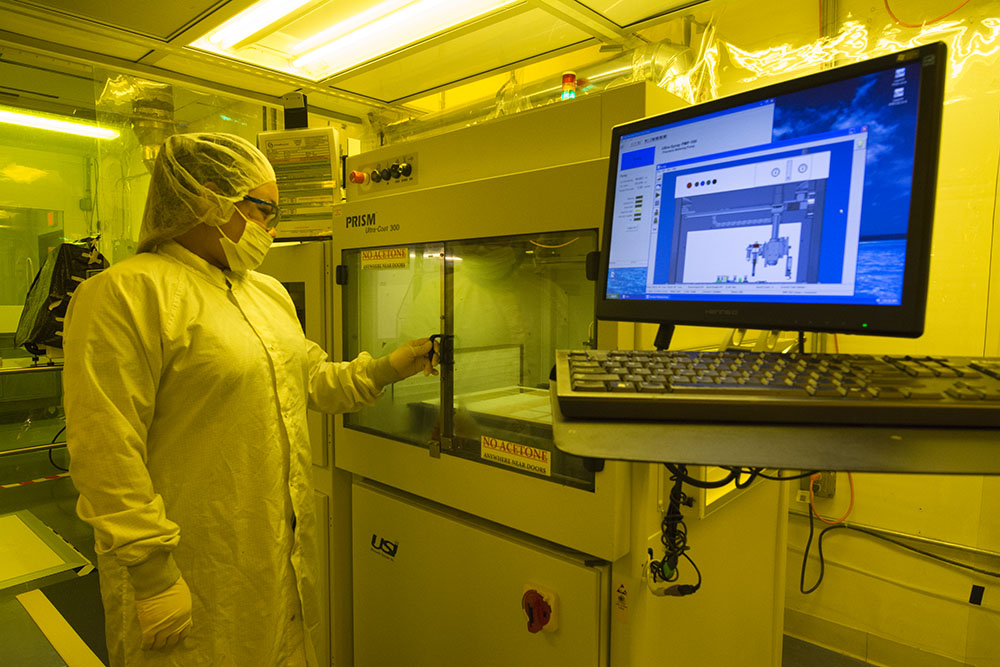

Our quality is second-to-none

In a world of customization and technical challenges, we understand the importance of customer service, communication, and process control. From the moment you request a quotation to the moment your product is shipped, we strive to let you know we’re on top of the details. Nothing is more important to us than delivering circuits the way you want them, when you need them.

CONTINUOUS IMPROVEMENT

Our management team has developed rigorous Continuous Improvement (CI) methodologies in order to eliminate problems that affect the cost, delivery, and quality of the custom thin film products we build. These CI methodologies can best be summarized as:

- Finding the true root cause(s) of undesirable events

- Identifying and implementing corrective actions

- Assessing the effectiveness of corrective actions

- Preventing recurrence of the undesirable events

Our QA system includes:

- Quality Assurance Manual

- Documented Quality Procedures and Visual Manufacturing Procedures

- 100% inspection of all critical incoming materials

- Equipment maintenance meets MIL-C-45662 and ISO11012-1

- Sputter lot coupons maintained on file for a minimum of three years

- Testing available per MIL-STD-883 or MIL-PRF-38534

- 100% inspection of each order to meet/exceed MIL-STD-883 (Method 2032) as well as customer specified requirements

- First article inspection reports available upon request

ULTRASOURCE IS REGISTERED TO AS9100

Our quality assurance system is based on AS9100. Our Thin Film products are 100% visually inspected to meet and exceed customer and MIL-STD-883 (Method 2032) requirements AS9100 Certification (pdf).

PROBLEM SOLVING

We employ the 8D or 8 Discipline approach as a team-oriented problem solving method for tackling problems.

The 8D process was invented at Ford Motor Company in 1987 and follows the Plan-Do-Check-Act (PDCA) model. Please fill out the form to the right to view the full 8D.

RESTRICTION OF HAZARDOUS SUBSTANCES (RoHS)

UltraSource thin film fabrication in accordance with European RoHS Initiatives UltraSource is a premier supplier of custom thin film manufactured devices to electronic and industrial markets and is fully committed to supporting Restriction of Hazardous Substances (RoHS) set forth by the European RoHS 2.0 Directive 2011/65/EU.