Laser WaterJet Machining Services Now Available at UltraSource

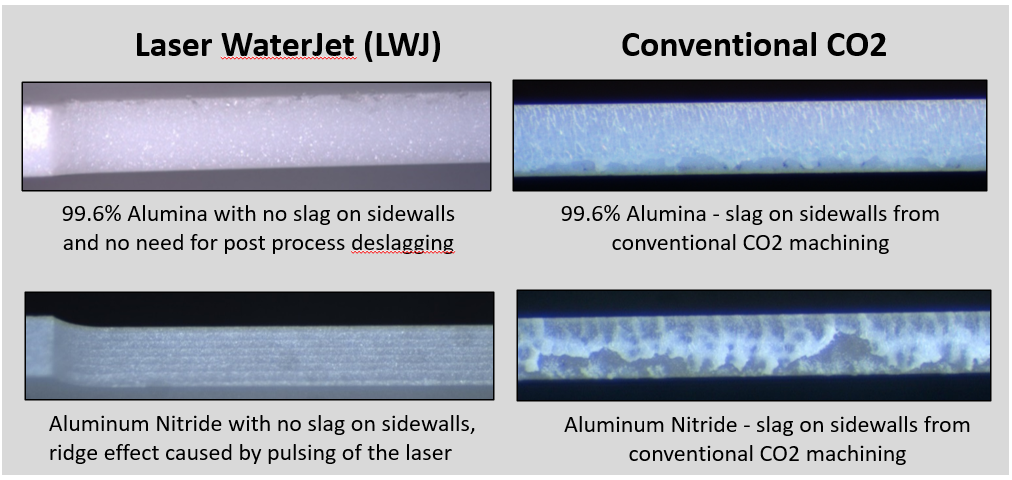

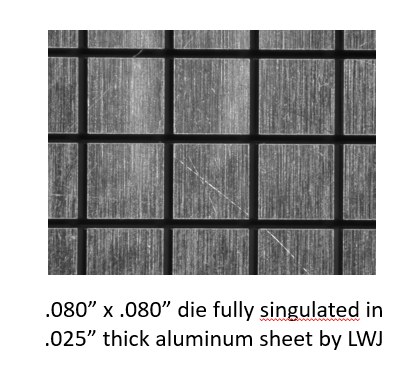

The Laser WaterJet (LWJ) is a new method for machining most ceramics, hard materials, and metals. The LWJ equipment precisely guides a laser beam down a waterjet, in a manner similar to light traveling through an optical fiber. The benefits of combining a laser and waterjet are:

- Enhanced cooling of the cutting area and substrate

- Efficient removal of machining debris

- Significant reduction in molten slag re-deposition

- Elimination of micro-cracking due to short duration pulses of the laser beam

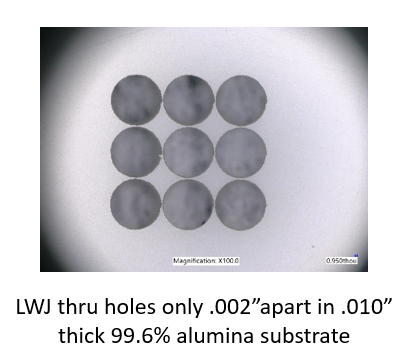

- Reduction in taper because the laser fills the waterjet column

| MATERIALS | LWJ COMPATIBLE |

| 99.6% Alumina | X |

| 170 W/ mk AIN | X |

| Sapphire | X |

| Diamond | X |

| Silicon Carbide | X |

| Coorstek TD-36 | X |

| Aluminum | X |

| Copper | X |

| Stainless Steel | X |

| PZT | X |

| BeO | X |

| Fused Silica | X |