What We Offer

Team Up With UltraSource and Chart a Course for the Future

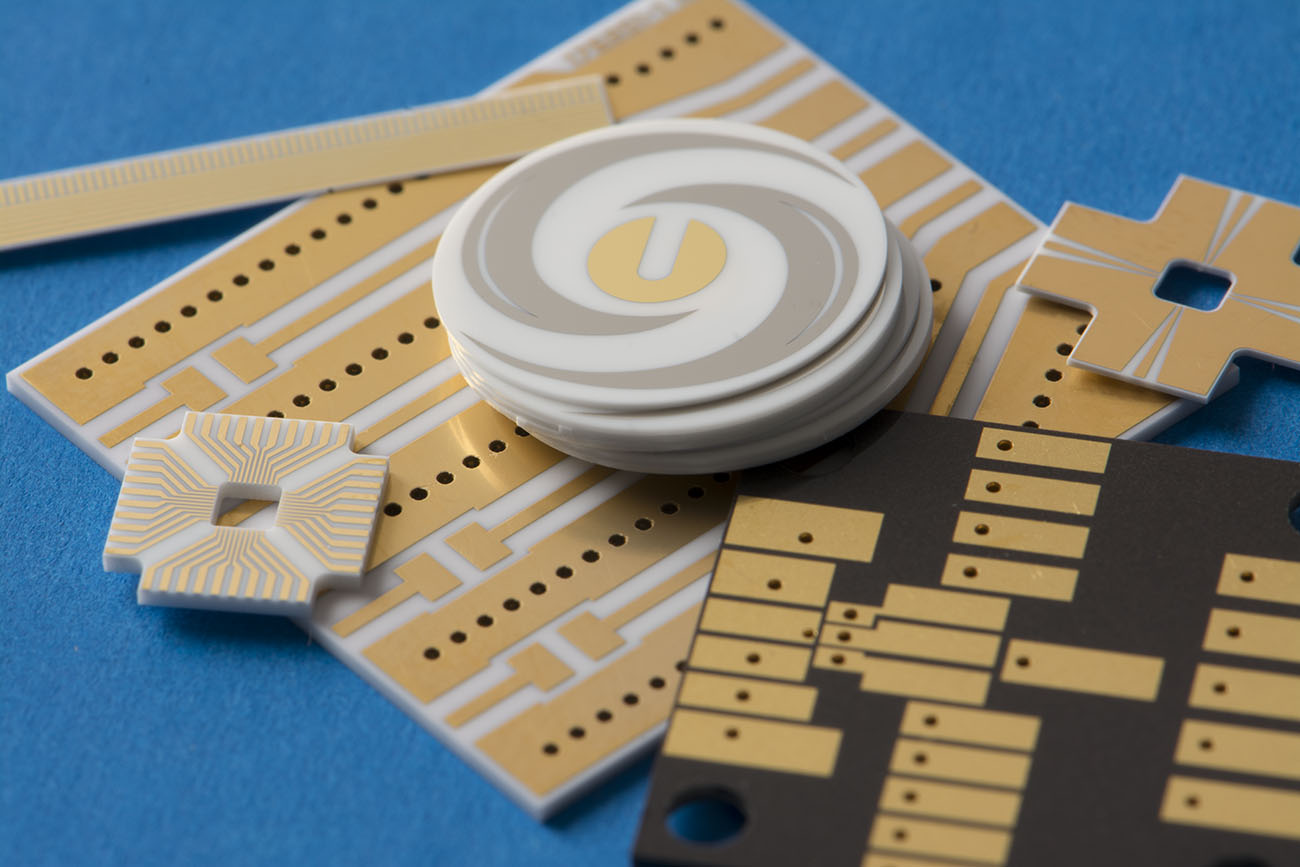

When you choose UltraSource as your thin film manufacturing partner you get more than a world-class design, manufacturing and processing facility at your service, you get to take advantage of the latest innovations in thin film today. Innovations and technology that will not only help you solve critical size/performance issues, but will also allow you the freedom to integrate the latest and most advanced multilayer thin film techniques and functions into your RF and microwave circuit and component designs.

Summary of UltraSource Services